The Curse of Unoriginality

TL; DR: From a large number of independent random samples, the average of system architectures devised to solve a particular problem converges to the most optimal one, if it exists. We can call this the curse of unoriginality.

In simpler words, if you want to create something useful, you may need to stick to creating something similar to what exists. This sounds awful from the outset, as if we’re destined to be unoriginal in order to succeed and, what is more, that innovation could in fact be counterproductive. We will see that it’s not the case…as long you’re aware of the curse. Let’s talk some examples.

See excavators for example. The ones used for digging holes in roads and that. They look.all.the.same. They all have the obligatory cabin, the articulated boom, the bucket, wheels, or endless tracks1. If you were to found the next Liebherr tomorrow, I bet we could easily predict what your excavators would look like with pretty high precision. When it comes to excavators, the only way manufacturers have found to differentiate from each other is by painting the damn machines in different colors…

See cars. They look more or less all the same. Sure, a Prius and a McLaren Speedtail have dramatically different characteristics…but the main architectural traits are the same: four wheels, a cockpit, a trunk, a steering wheel, rear lights, front lights, doors on the sides; you get the score. You could get off your Corolla and go drive a Lambo without too many problems. Remember, the curse is about architecture, not about performance or aesthetics. That’s how automakers differentiate from each other when they are cursed to share the same established architecture that’s been around for more than a century.

Take now geostationary satellites: they look all the *exact* same. A box, two big wings of panels, and a set of antennas of some kind. Antennae may vary, but the big traits are there. The software on board satellites is also cursed with unoriginality: it might be written in C, Ada, or whatever. It might run on Linux, RTEMS, or bare metal, but all have the same building blocks: command and data handling, failure handling, telemetry handling, etc. When writing flight software for satellites, you’re cursed to be unoriginal because there are decades of space technology behind you telling you what has worked before.

See aircraft now, in particular airliners: the tube-and-wing architecture settled several decades ago as it proved to be the most efficient system architecture. Check any flight over your head and you will see the curse in motion: the long tube, the two engines2, and the horizontal stabilizer.

The curse—this strange phenomenon where products within a category look similar across different vendors or manufacturers—is influenced by several factors, often shaped by practical, ergonomic, and regulatory considerations rather than any natural "law” of sorts. I’ll venture myself into listing some probable reasons why many technical products end up sharing similar features and architectures:

Functional Optimization

Certain design features are dictated by the function and purpose of the product. We discussed excavators before: well, they surely need a stable base, a powerful arm, and a cabin for the operator. This leads to a similar overall form across different manufacturers. Similarly, satellites do require power on board, data links, and propulsion systems, which gives us a hint of how it kinda drives a common design.

Ergonomics and User Requirements

Ergonomics plays a significant role in product design. For instance, the excavator operator's cabin must be designed for comfort and control, influencing the layout and features. Devices like smartphones share similar shapes and sizes because they need to be held comfortably and fit in our pockets. Go and try to convince investors about your great idea of a triangular phone. You would surely come back empty-handed; there’s a reason why they’re flat and compact. Go try to design a car that will require customers to re-learn from scratch how to drive.

Engineering and Manufacturing Constraints

The materials and manufacturing processes used can lead to similarities in design. Certain shapes and structures are better suited to withstand stresses and strains. Also, standard manufacturing techniques (like casting, molding, and machining) may favor certain shapes and designs versus others.

Standardization and Regulations

Regulatory bodies often set standards that products must adhere to for safety, interoperability, and performance. In the automotive industry, vehicles must meet safety regulations that influence their design, leading to similarities. Satellites must meet specific requirements and constraints for fitting in increasingly standardized launch vehicles, which might favor their “box” shape with foldable appendages galore. For aircraft, anything other than tube-and-wing would face big challenges while being serviced in today’s airports globally, making the design economically impractical, as “cutting edge” as it may appear.

Market Trends and Consumer Expectations

Companies often follow trends to meet consumer expectations and preferences. While functional, products also need to be visually appealing and consistent with brand identity. Manufacturers often emulate successful designs to remain “current” and thus competitive.

Convergent Evolution in Design

Originally a biological concept, convergent evolution refers to the process by which unrelated organisms independently evolve similar traits as a result of having to adapt to similar environments or ecological niches. In design, this concept is used to explain why different designers might independently create similar solutions to similar problems.

Benchmarking and Best Practices

Companies often study and adopt best practices and successful designs from competitors. Learning from the successes and failures of others can lead to certain convergence in design.

Path of Least Resistance (aka, laziness)

Designers might choose the easiest path to achieve a goal. This can translate to adopting widely accepted and proven design conventions to minimize resistance from users and manufacturing processes or lead to the adoption of designs that have been proven to work reliably and consistently. Or by adopting “reference designs” that save them the time and effort of starting from scratch.

Mimetic Isomorphism

A complicated term to say: blatant imitation. Mimetic isomorphism is the tendency of an organization to imitate another organization because the latter appears to be more successful or legitimate. In product design, this manifests as companies imitating successful designs from competitors to achieve similar success. Want an example? See the trend years ago when cars replaced the classic monopole antenna for the “fin” antennas. First, it was one single automaker (who probably ripped it off from aerospace), and soon everybody followed. More recently, another similar trend is that silly “feature” of cars switching off headlights while making a turn…as if turning lights and headlights could not coexist. It will require some pedestrians to be run over for the industry to realize that reducing light power during turns was a stupid idea.

All being said, and with the curse of unoriginality hanging on top of our heads, is there any room left for innovation, then, or what? There is, but such innovation cannot grow unaware of the curse. The only way out is to be innovative while navigating through the established architectures, which are established for good reasons; they have survived the test of time and a myriad of iterations.

There are successful, high-profile cases of innovation of top of established architectural traits. SpaceX managed to introduce innovation to launch vehicles although launcher architecture was established more than 50 years ago, with an engine at the bottom, a set of staged sections that also host the tanks, and a payload at the tip. SpaceX introduced the concept of reusability in the first stage, which hadn’t been done before. The innovation was done—not without some headaches—while keeping the overall architectural traits, somehow honoring and leveraging the decades of convergence of rocket architecture.

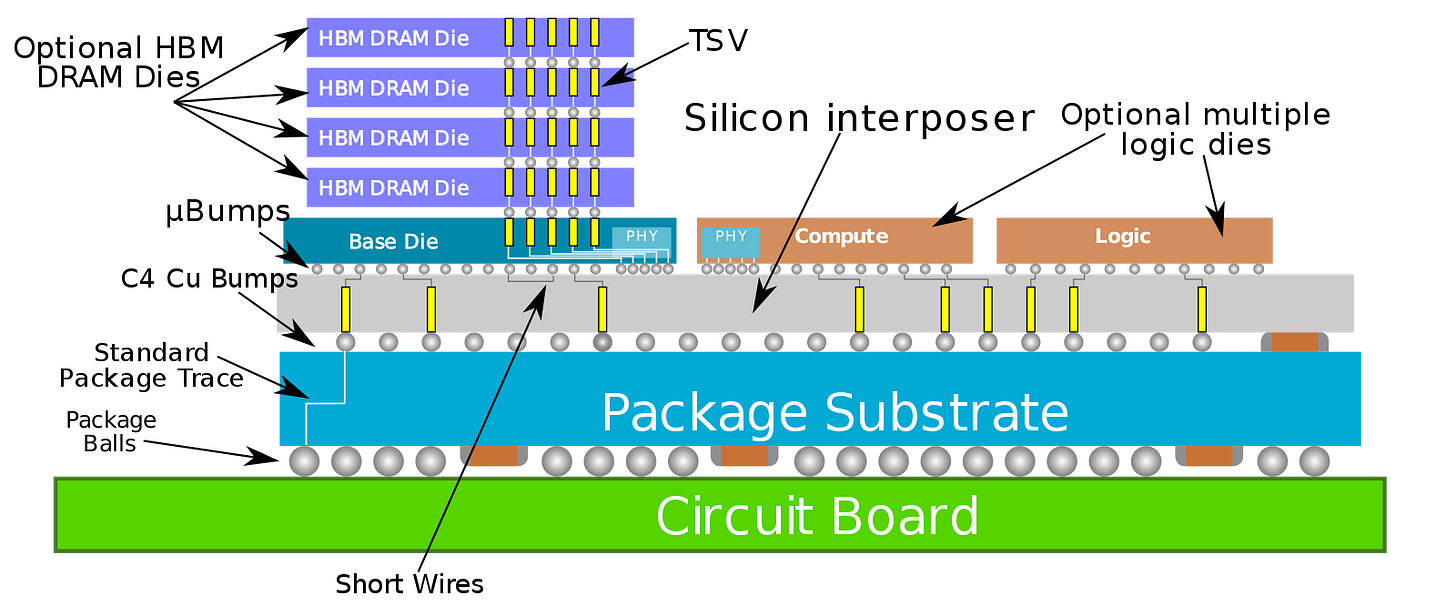

There are more examples, for instance, chip manufacturers who keep on pushing integration limits while sticking to the well-established integrated circuit approach. See the Chip-on-Wafer-on-Substrate (CoWoS) package which is practically an entire city inside a chip.

In short, we are as product designers somewhat cursed to be unoriginal, to follow the established architectures that have taken ages to form and are shaped by a myriad of factors we do not control. But this does not mean we are cursed to be boring and repetitive; our creativity needs to be put not into creating something so radically new that will never work because of sheer impracticality but into creating stuff that inherits from something that exists and makes it a hundred times better.

John Gall put it beautifully quite some time ago:

All complex systems that work evolved from simpler systems that worked.

By the way, what an awful sound crawler excavators make when they roll, what the heck is wrong with those? Can’t someone engineer some of those that do not sound like a million unoiled doors are being opened at once?

Twin-engine aircraft are the most popular today since their fuel efficiency is much better than a 4-engine aircraft.